With eccentric and hydraulic presses from 45T to 400T capacity, Ciclope Automotive operates in full compliance with the PPRPS. To ensure greater production flexibility, material savings and agility in set-ups, the plant has modular, progressive and transfer tools, longitudinally moving material feed systems and movable table presses.

Ciclope Automotive works with manual and robotic resistance welding, projection and MIG processes of up to 300 KVA. The factory also has test devices to guarantee product quality.

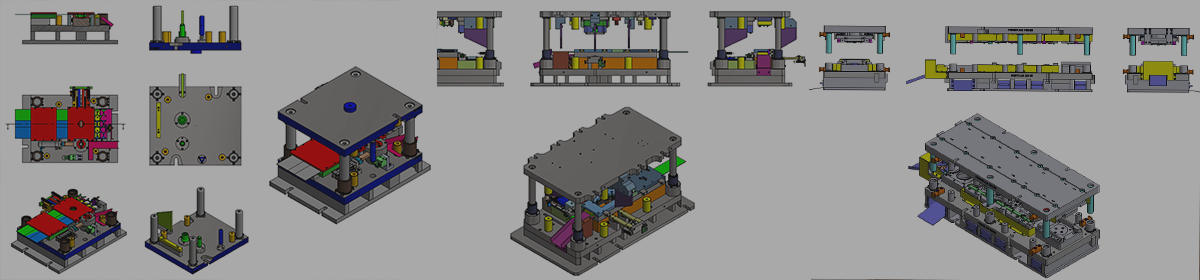

Ciclope Automotive, through its own construction tools, operates in the construction and updating of modular and progressive devices and tools for its customers. Currently, Ciclope Automotive has a portfolio of more than 80 tools, tailored for its customers.

Ciclope Automotive, through its own maintenance tools, operates in the repair of modular and progressive tools and devices transferred to its customers, thus ensuring the extension of the useful life of the tools and the quality of the product.

With high precision CNC cutting saws, Ciclope Automotive, with its colligated enterprise RDR Automotive, operates in the process of cutting pipes and rods for the automotive industry. In line with this process, Ciclope Automotive also operates in the process of machining, reducing and expanding pipes, which are intended for sale or use in the manufacture of assemblies in other sectors of the factory.

With an experienced engineering department, Ciclope Automotive develops the entire manufacturing process, from stamping simulation to finishing. Applying the PPAP tool and using the most modern project software, the development is carried out with a focus on quality and efficiency, taking into account specific customer requirements, assembly interface, functional performance, packaging and transport, thus ensuring compliance with deadlines. development and customer satisfaction.

Trucks and transportation service with deliveries throughout Brazil.

Process and product control laboratory equipped with modern 3D dimensional, chemical, layer thickness equipment. , macrography, metallography.